MERCED, CA – November 22, 2021 – Maas Energy Works announced today that the Merced Pipeline Project will go online by December 3, 2021. Merced Pipeline is a multi-farm anaerobic dairy digester project developed by the leading digester developer, Maas Energy Works. The project entails partnering with multiple dairy families in the area to build covered lagoon digesters on each farm. Each covered lagoon captures naturally occurring methane gases that would otherwise escape from stored manure and vent into the atmosphere. Instead, the covered lagoon captures the escaping “biogas”, capturing and beneficially using methane emissions.

The Merced Ribbon Cutting Ceremony to celebrate the successful commissioning of the facility will occur December 6, 2021, at the Hub location. The Maas Energy team will invite guests comprised of key personnel from state agencies that partnered with this project such as California Department of Food and Agriculture, California Public Utilities Commission, and California Energy Commission, plus engineers and key contractors who helped construct the facility, local & foreign investors of the project, state officials along with the partnering dairy producers who helped make this possible.

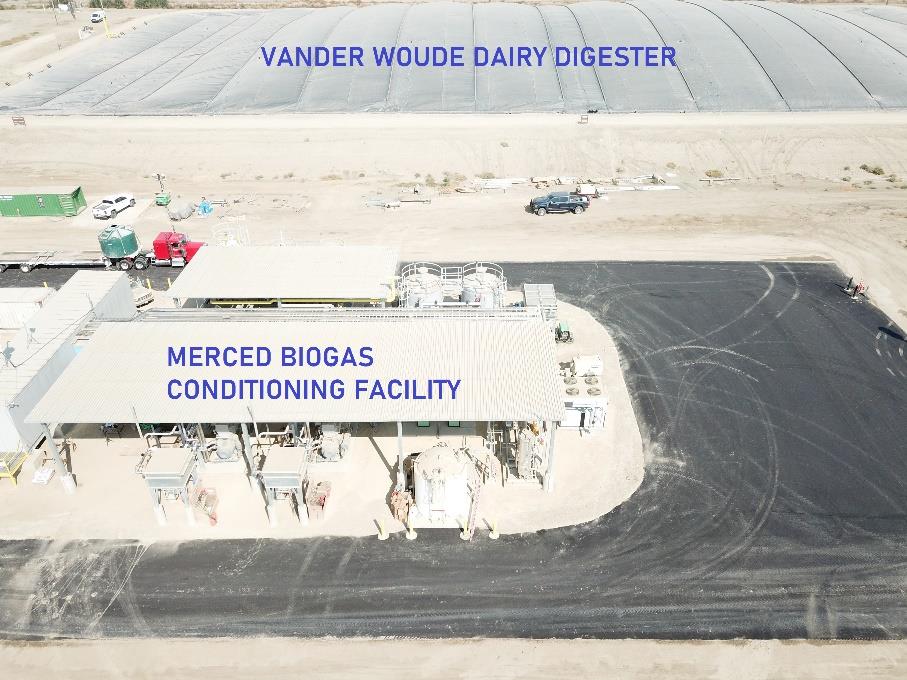

The Merced Pipeline Biogas Conditioning facility will upgrade the dairy biogas to biomethane (aka Renewable Natural Gas or “RNG”) for utility pipeline injection. Merced Pipeline has executed a Purchase and Sale Agreement with third-party pipeline operator, California Energy Exchange Corporation (CEEC), to inject the product biomethane into their existing mid-market collection pipeline that serves the project area. This arrangement takes advantage of existing private pipeline infrastructure to increase speed of execution and give the project much larger expansion capability than adding in more utility pipelines. This partnership with CEEC will in turn delivers the gas to the PG&E utility backbone pipeline under their existing interconnection agreement. Renewable attributes for the RNG are transferred directly to Waste Management and used at their CNG stations throughout California to make Renewable Compressed Natural Gas (R-CNG) transportation fuel.

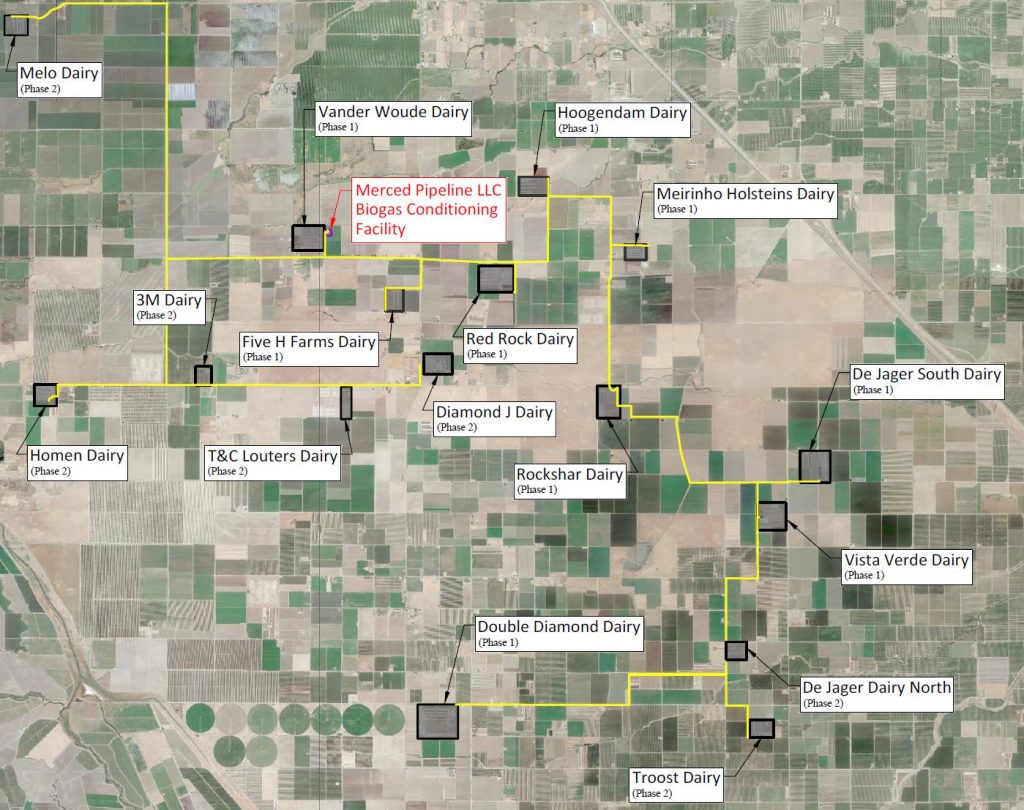

To collect this gas, Merced Pipeline will construct a series of private gathering lines to transport all the gas created at each digester to a centralized conditioning facility south of the city of Merced.

There are currently sixteen participating dairies in this cluster with several more potential future expansion dairies in the project area. These sixteen digesters will be built out in two phases. Phase 1 includes 9 digesters that are in final stages of construction and will come online in the next 0-5 months. Phase 2 includes an additional 7 digesters that are currently in permitting and design and will come online in 2023.

The Merced Pipeline project will significantly reduce dairy methane emissions. When Phase 1 (first nine digesters) is completed in the coming months, Merced Pipeline will be capturing over 147,000 tons of Carbon Dioxide equivalent (CO2-e) from over 32,000 cows that would have been released into the atmosphere. The biomethane will then be utilized by delivering over two million gallons of fuel a year into the California CNG market. By capturing the naturally occurring methane that was previously escaping into the atmosphere and converting it to CNG fuel, Merced Pipeline is able to not only significantly reduce the GHG emissions from dairy, but also reduces a variety of pollutants that would otherwise enter the stressed San Joaquin Valley airshed. the Sulphur emissions (H2S) on the dairy as well. Fueling CNG heavy duty trucks brings with it an additional benefit of reducing NOx emissions on the roads by 80-90% from a standard diesel truck. When Phase 2 wraps up in 2023 the fuel production and GHG capture statitics mentioned above will all increase by an additional 70-80%.

Working in partnership with multiple state agencies (CPUC, CEC, and CDFA), the Merced Pipeline cluster will be a part of the initial pioneers to successfully demonstrate the ability to deliver dairy CNG clusters to market, near-term achievement of GHG benefits, and Criteria Pollutant emissions reductions both on dairies and on the California roadways. The Merced Pipeline cluster is also creating and supporting hundreds of jobs in the Central Valley of California.

About Maas Energy Works

Headquartered in Redding, California, Maas Energy Works is one of the largest digester developers in the U.S, turning produce methane into compressed natural gas. Maas Energy Works was the developer for Calgren Dairy Fuels, the largest dairy biogas operation in the U.S and is now actively developing in a dozen states. The Merced Pipeline Biogas Conditioning Facility will be Maas Energy Works 3rd dairy renewable natural gas facility built in California. Another Biogas Conditioning Facility is scheduled to finished construction & go online to add to MEW’s portfolio by January 2022. Maas Energy employs over eightyfull time dairy digester professionals who job is to create “renewable energy that works.” For more information, please go to: www.maasenergy.com.