At Toyota Tsusho America, we are actively involved with innovative projects in power generation across North America. On a global scale, we provide support to our parent company, Toyota Tsusho Corporation with the development of power generation.

We also provide valuable cost-saving solutions to energy companies in the U.S., Canada and Mexico by sharing our production know-how as well as the development and integration of modern, connected technologies such as Toyota Tsusho America Smart Factory Solutions.

We integrate advanced manufacturing technology with existing production lines to produce efficiency gains, improve quality and to streamline maintenance. Our SMART FACTORY SYSTEM improves data visibility and helps make the best use of the equipment you already own and provides a clear upgrade path for the future.

Toyota Tsusho has invested in manure digesters that capture methane gas emissions that would otherwise escape into the atmosphere. Since methane is a potent greenhouse gas, trapping 86 times more heat in the atmosphere than carbon dioxide, these projects deliver important environmental benefits. The captured biogas is also a valuable, energy-rich fuel that can be used for renewable electrical generation supplying power to the grid or onsite needs.

Toru S. is a senior manager in the Corporate Strategy and Sustainable Business Development Division at Toyota Tsusho America, Inc. (TAI).

His work focuses on the hydrogen value chain ecosystem in the mobility industry trying to create supply and demand synergy to accelerate its market expansion.

He and his team are bringing Toyota Tsusho’s experience of several environmental demonstration projects in Japan to the U.S to help establish a sustainable clean energy society.

He is currently involved in a demonstration project for fuel cell port equipment and hydrogen supply solutions at the Port of Los Angeles and Long Beach. His team and partner companies plan to develop a sustainable green hydrogen supply scheme for the ports with biogas from dairy farm digesters from Central Valley in California.

We leverage our years of automotive experience to assure all machine features and functions meet your design and production needs. Toyota Tsusho America provides complete, turn-key site management. We also prioritize compliance and safety, meeting or exceeding all PSHSR, CSA and UL certification requirements.

The automotive industry has become one of the most innovative industries in the world. Whether you need to increase throughput, quality or profitability, we are the leaders in automation/robotics equipment sourcing, maintenance and technical support.

Our technical support team sets the standard for start-up production support and technical training. We also provide supply chain support, repair and spare parts services, which reduce down time and production delays.

Toyota Tsusho America operates a full-service supply chain network with value added services such as kitting, repacking, sequencing, sub assembly and project management. We provide a single point of contact for thousands of vendors and OEMs worldwide and offer full warehousing and inventory management.

We deal with local currency based on your company’s specific requirements, reducing foreign exchange risk. We also provide high-quality administrative services, reducing administrative costs, lead times, and floor space requirements.

Through our global channels and 5,000+ vendors we provide consistent supply of machine spare parts, cutting tools and more. We also manage the purchasing of maintenance, repair and operations (MRO) items. Our logistics team can also provide high-quality stocking and kitting services, including stocking agreements, forecasting, and support for repairs/rebuilds.

Los Angeles, CA

Troy, MO

Silao, Mexico

Chicago, IL

Maryville, TN

Georgetown, KY

San Antonio, TX

Apaseo el Grande, Mexico

Tupelo, MS

Huntsville, AL

Princeton, IN

Eleanor, WV

Monterrey, Mexico

San Luis Potosí, Mexico

Farmington Hills, MI

Woodstock, Ontario

Cambridge, Ontario

Based in Georgetown, Ky., Industrial Tech Services, Inc. (ITS) provides Toyota, Toyota-related companies, and all other industries effective products and services to meet their needs.

It is ITS’s desire to operate a quality planning, assembly, installation and service company oriented toward customers’ perceptions of satisfaction.

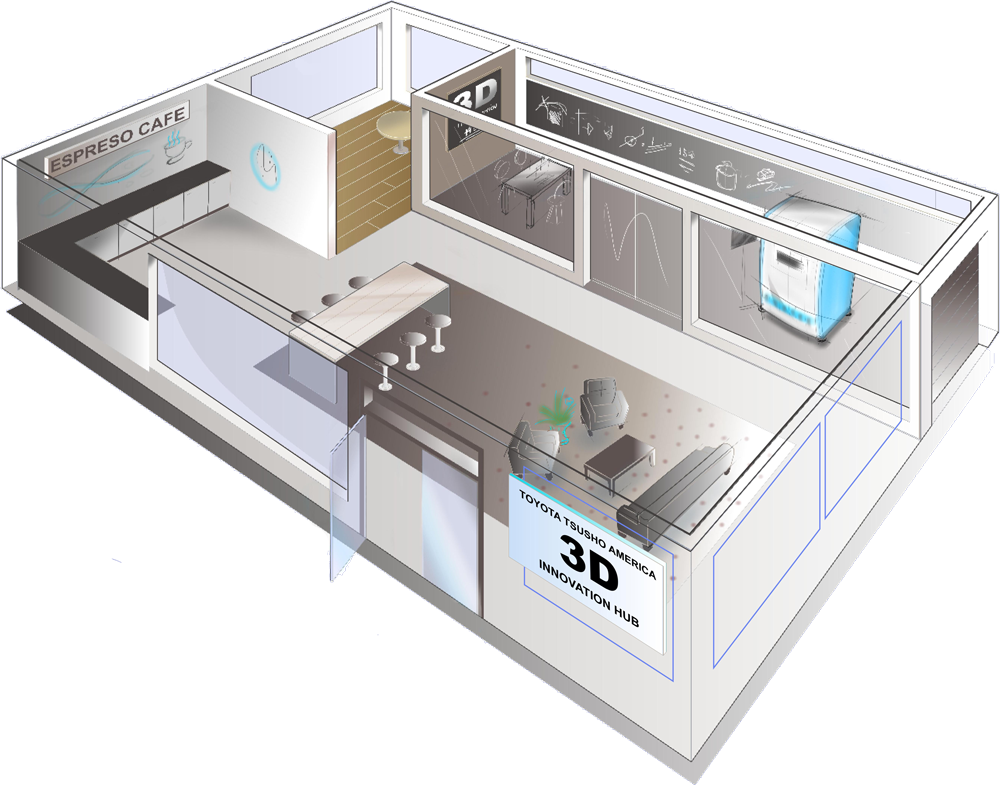

Jason K. is the director of our 3D Innovation Hub and has been with Toyota Tsusho America since 2003. During his time here, Jason has held a variety of key positions including sales, marketing, and management within our Machinery Division.

He created the 3D Innovation Hub with the next generation of professionals in mind. A place to imagine, develop, and test new technology that drives new business as well as a place where team members gather to learn from one another. Jason sees the value of this collaboration every day, stating “It’s amazing to witness the progress when people work together, focusing on new solutions to big challenges. That’s when we all grow personally and professionally.”

With a mission to create an environment where people, ideas, and knowledge come together to form concepts, prototypes, and breakthrough solutions, the Toyota Tsusho America 3-D innovation lab fosters creativity, enables development and opens doors to new relationships. This hands-on facility houses 3D printers (both polymer and metal materials), mold design (injection molding and die casting) as well as low volume manufacturing and short-run production support.